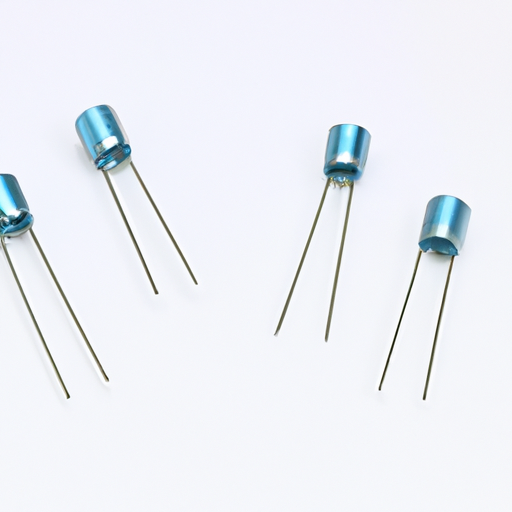

CFR-25JB-52-110K NTC Thermistors highlighting the core functional technology articles and application development cases of NTC Thermistors that are effective.

Core Functional Technology of NTC Thermistors

1. Temperature Sensitivity: NTC thermistors, such as the CFR-25JB-52-110K, are designed to exhibit a significant change in resistance with temperature variations. This characteristic allows for precise temperature measurements, making them suitable for applications requiring high accuracy.

2. Resistance-Temperature Characteristics: The relationship between resistance and temperature in NTC thermistors can be described using mathematical models like the Steinhart-Hart equation. This enables the conversion of resistance values into temperature readings, which can be calibrated for specific applications, enhancing measurement accuracy.

3. Fast Response Time: NTC thermistors respond quickly to temperature changes, which is crucial for applications that require immediate feedback for temperature control. This rapid response time is essential in dynamic environments where temperature fluctuations occur frequently.

4. Compact Size and Low Cost: The small form factor and cost-effectiveness of NTC thermistors make them ideal for integration into a wide range of electronic devices. Their low profile allows for easy placement in tight spaces without adding significant costs to the overall product.

5. High Stability and Reliability: NTC thermistors are known for their long-term stability and reliability, even under varying environmental conditions. This makes them suitable for applications that demand consistent performance over time, such as in medical devices and industrial monitoring systems.

Application Development Cases

1. Consumer Electronics: In consumer electronics, NTC thermistors are integral to devices like refrigerators and air conditioners, where they help maintain optimal temperatures. For instance, in refrigerators, they monitor internal temperatures to ensure food safety and energy efficiency.

2. Automotive Applications: NTC thermistors play a critical role in automotive systems, including engine temperature monitoring and climate control. For example, they can be used in engine coolant temperature sensors, providing data that helps optimize engine performance and fuel efficiency.

3. Medical Devices: In the medical field, NTC thermistors are essential for devices such as digital thermometers and incubators. Their accuracy is vital for patient monitoring, ensuring that temperature readings are reliable for diagnosis and treatment.

4. HVAC Systems: NTC thermistors are widely used in HVAC systems to monitor and control air and fluid temperatures. They help maintain comfortable indoor environments while optimizing energy consumption, contributing to overall system efficiency.

5. Industrial Applications: In industrial settings, NTC thermistors are utilized for temperature monitoring in manufacturing processes and equipment cooling systems. Their robustness allows them to function effectively in harsh environments, ensuring operational safety and efficiency.

6. Renewable Energy Systems: In renewable energy applications, such as solar inverters and electric vehicle battery management systems, NTC thermistors monitor the temperature of batteries and other critical components. This monitoring is essential for preventing overheating and ensuring safe operation, thereby extending the lifespan of the systems.

Conclusion

The CFR-25JB-52-110K NTC thermistor exemplifies the core functional technology of NTC thermistors, providing precise temperature measurement, rapid response times, and reliability across various applications. Its versatility makes it a crucial component in consumer electronics, automotive systems, medical devices, HVAC systems, industrial applications, and renewable energy systems. As technology continues to evolve, the role of NTC thermistors in temperature sensing and control is expected to expand, leading to further innovations and applications in diverse fields.